Forget casting or injection molding. 3D printers for metals have arrived on the market. Though expensive, they are used for prototyping and are not intended for mass production due to the expensive materials used for printing.

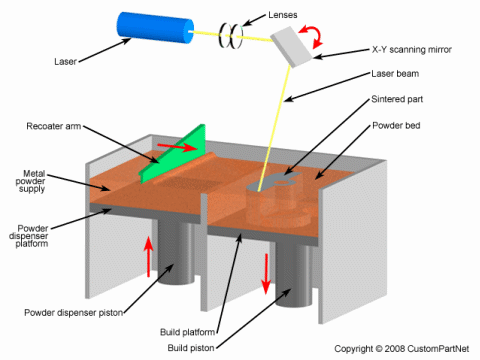

These printers use the “direct metal laser sintering” (DMLS) technology. DMLS technology is based on the use of a laser beam to melt 20-40 mic. thick layers of metal powder (most often stainless steel, aluminum, bronze and titanium). These layers are placed one above the other to form the end product. This technology is commonly used in the aerospace industry as well as in the medical industry for complex products which result from development departments of companies.

The products of DMLS technology have excellent mechanical properties of the base material, and in contrast to previous methods they have the characteristics of solid material with no cracks or internal cavities. In this way prototypes are fully functional and can be subjected to various tests before mass production. This technology achieves the production of parts that modern CNC machines can notproduce.

Some of the products that are obtained in this way you can see the http://youtu.be/PHaXX2OoOs4